Digital Transformation Made Simple

Easy Ways to Get Actionable Data from Your Plant Floor

In today's fast-paced world, every business needs a digital edge. Digital Transformation (DX) combines traditional manufacturing with new technologies to derive meaningful and actionable insights to improve your plant floor processes. Without DX, it can be challenging to keep up with demand, maintain high-quality production, and adapt to changing market conditions.

With our innovative solutions and expert team, Kendall Electric can help demystify DX and give you a better understanding of what's happening in your factory with simple solutions that will connect plant floor data to real-time systems.

>90%

of manufacturing leaders believe that DX is important for their success.

Source: Forrester Consulting

Improve Product & Process Traceability

Gain visibility into your manufacturing process to make data-driven decisions.

Optimize Maintenance & Repair

Predict potential issues

and product health from

plant floor data.

Minimize Energy Consumption

Reduce energy waste, promote efficient resource allocation, and save energy costs.

Save Labor Costs & Reduce Overtime

Implement automated tasks to improve efficiency and save labor costs.

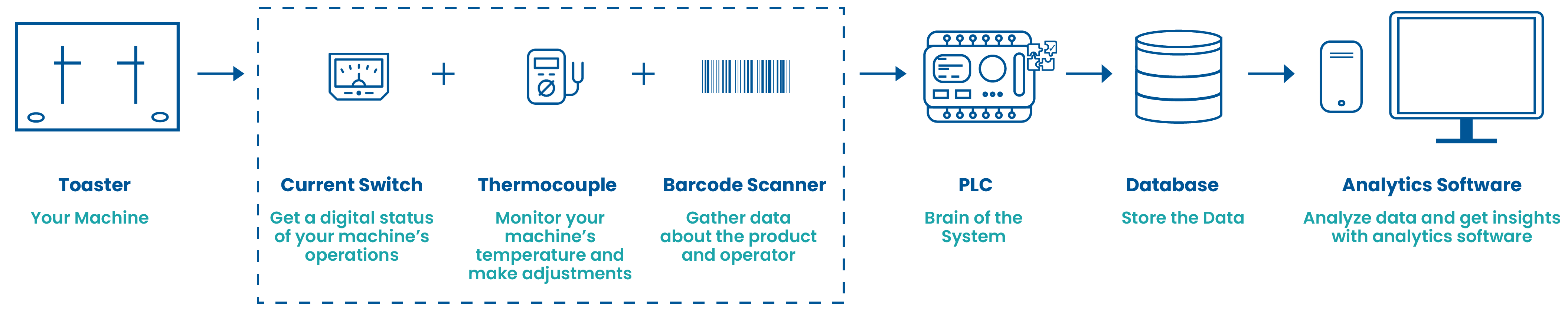

Extracting Insights from Ordinary Machines

DX is not just a technological upgrade; it can be applied to virtually any equipment or device on the plant floor to get data-driven insights and make improvements.

Whether you are looking to get a cycle count from a machine, reduce scrap, improve your OEE score, find out how long your line was down, or obtain reporting data, our expert team can help.

Watch this short 5-minute video to learn how you can extract multiple data points from a simple machine like a toaster.

What's the one device you would like to get data points from?

See how easily you can extract meaningful data from a simple machine like a toaster

Start Your DX Journey with Kendall Electric

Let Kendall Electric guide you on your DX journey. Whether you need help to remove roadblocks or guidance with software, hardware, or project management - our team can help to get you where you want to be on your digital journey.

Evaluate your current goals and assess your existing cost-saving strategies as you look inward at the digital initiatives in your organization with helpful insights from our experts.

Let Kendall Electric help you customize the process to make it as simple or as sophisticated as you want. Take the next step today!

Improve Product & Process Traceability

Gain visibility into your manufacturing process to make data-driven decisions.

Optimize Maintenance & Repair

Predict potential issues and product health from plant floor data.

Minimize Energy Consumption

Reduce energy waste, promote efficient resource allocation, and save energy costs.

Save Labor Costs & Reduce Overtime

Implement automated tasks to improve efficiency and save labor costs.